Welded joint monitoring in Heliuye Bridge

Brief:Overview: The Yangtze River Diversion project is a large-scale cross-basin water diversion project, which mainly focuses on the urban and rural water supply, the development of navigation along the Yangtze River, and the improvement of the ecological environment of Chaohu Lake and Huaihe River. Heliuye Steel plate bridge is one of the Bridges in the project. As a steel plate bridge, the bridge body is fixed by welding, and there are many welds in the whole bridge body. As a bridge with a span of

Overview:

The Yangtze River Diversion project is a large-scale cross-basin water diversion project, which mainly focuses on the urban and rural water supply, the development of navigation along the Yangtze River, and the improvement of the ecological environment of Chaohu Lake and Huaihe River. Heliuye Steel plate bridge is one of the Bridges in the project. As a steel plate bridge, the bridge body is fixed by welding, and there are many welds in the whole bridge body. As a bridge with a span of 180 meters, it bears great pressure, so the welding quality of the bridge is very important. Improper treatment of the weld is easy to occur large load and sudden fracture accident. Instead of the traditional ultrasonic weld detection, the customer chooses RAEM1 Intelligent Acoustic Emission Monitoring System for online monitoring of the weld in the bridge box girder perpendicular to the direction of the lane. The project was implemented in February 2023.

Working principle:

RAEM1 acoustic emission monitoring system can accurately detect the crack signal of the welded joint, process and analyze the signal, and then upload the signal to Qingcheng Cloud platform through 4G communication, so that customers can see the status of the bridge in real time on the terminal equipment. The built-in algorithm of the cloud platform software can trigger alarm when the crack signal of welded joint reaches a preset value, and notify customers by sending SMS or email.

Composition of RAEM1 Acoustic emission monitoring system:

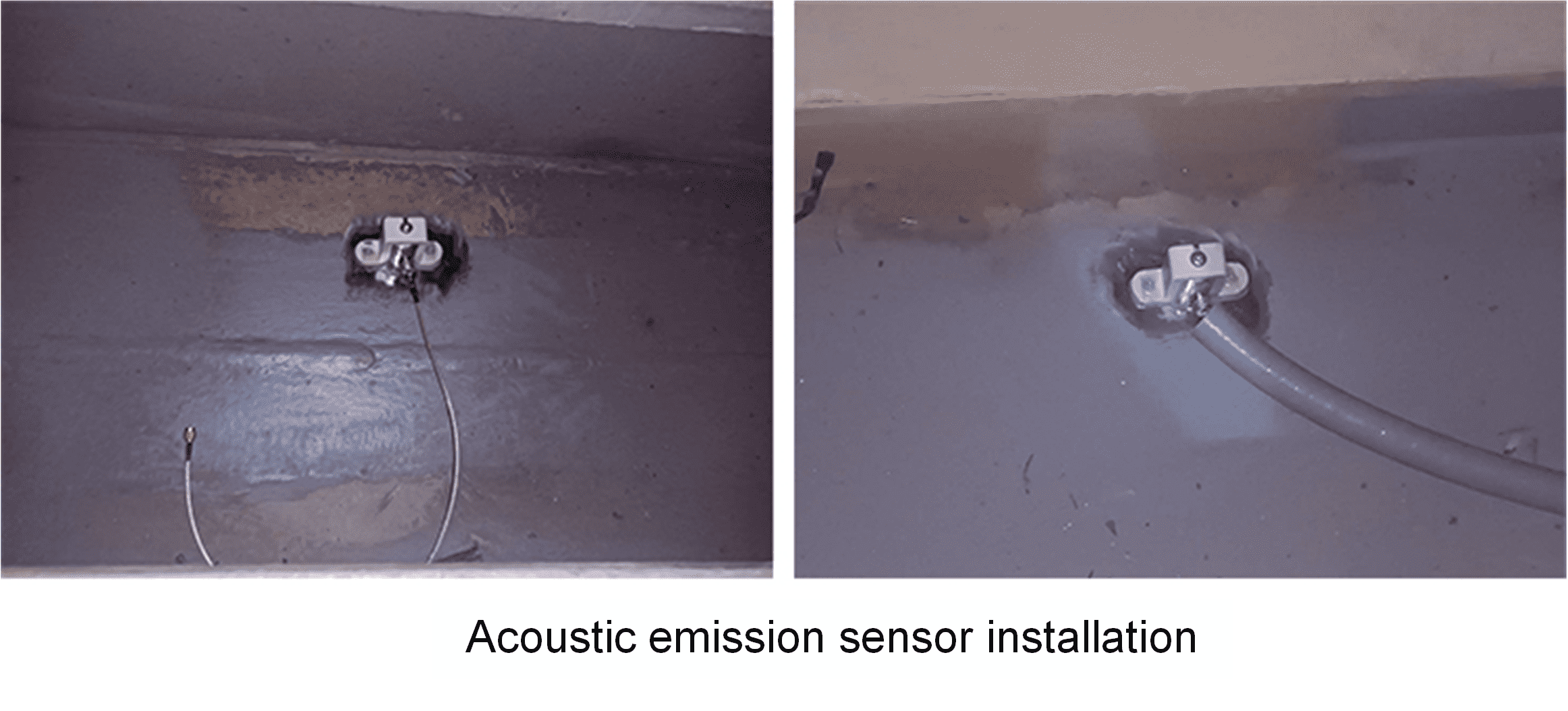

1. Acoustic emission sensor: it is installed near the welded joint of the bridge to collect the crack signal, convert the signal into telecommunication and transmit the signal to the RAEM1 monitor after amplification.

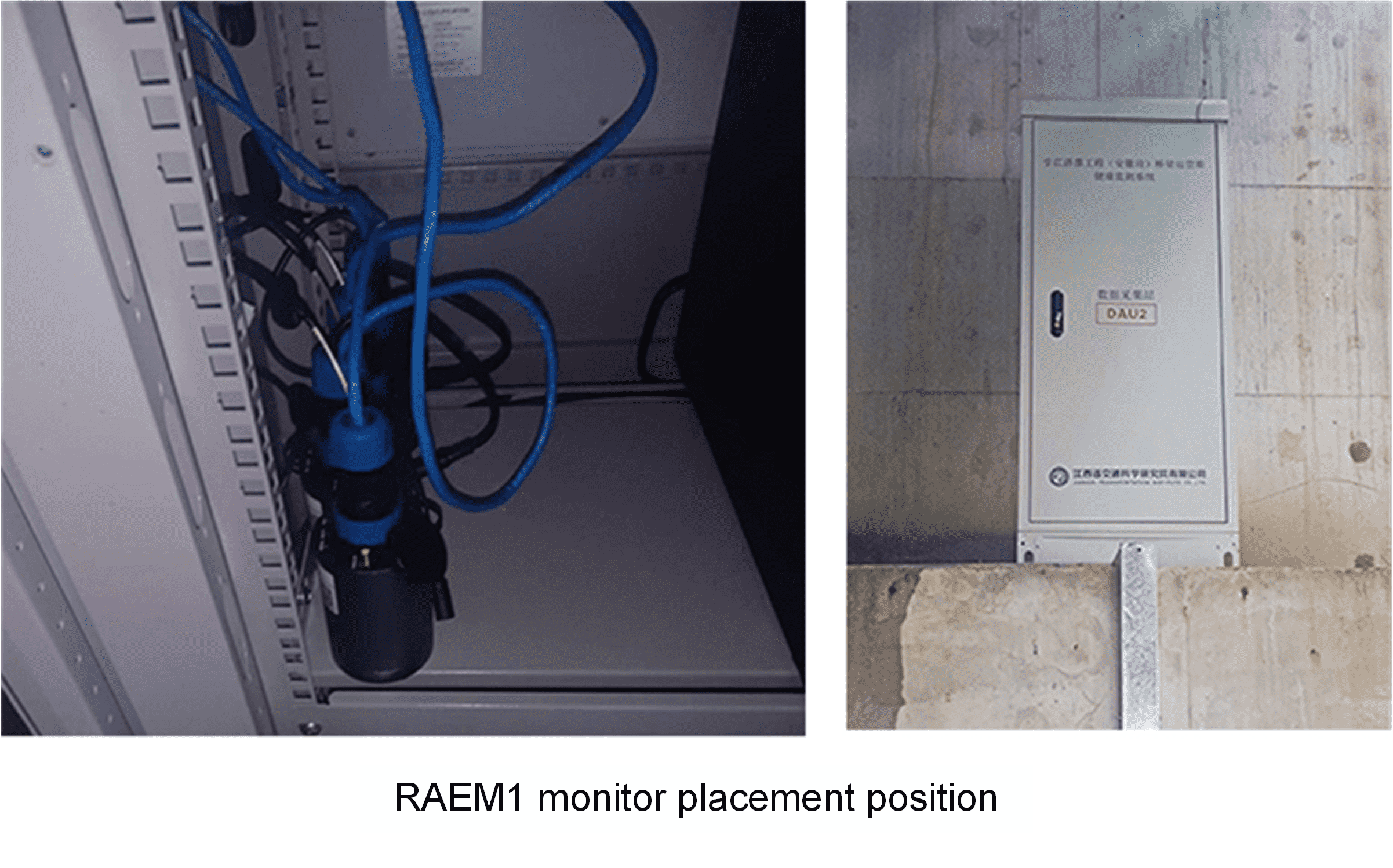

2. RAEM1 monitor: Analyze signals from sensors and upload data to the cloud platform.

3. Qingcheng Cloud platform: real-time display of monitoring data, and provide calculation and alarm functions.

Results:

Different from the traditional regular ultrasonic wave inspection of welded joint, RAEM1 acoustic emission monitoring system can not only carry out long-term unmanned monitoring welded joint of bridge body, but also accurately record the position of crack signal, crack time, number of cracks, and trigger the alarm to the customer's terminal equipment when the welded joint is abnormal.